Once the research, drawing and design has been done, making good models requires dedication, patience and a unique combination of skills. Probably some natural ability helps too, though a lot can be learned – eventually. Having said that, like many model makers I am largely self taught.

But having the right tools and being able to make good use of them will make all of this substantially easier. My workshop facilitates all of the processes I use to make a model, and the content of it constantly develops to better serve my needs.

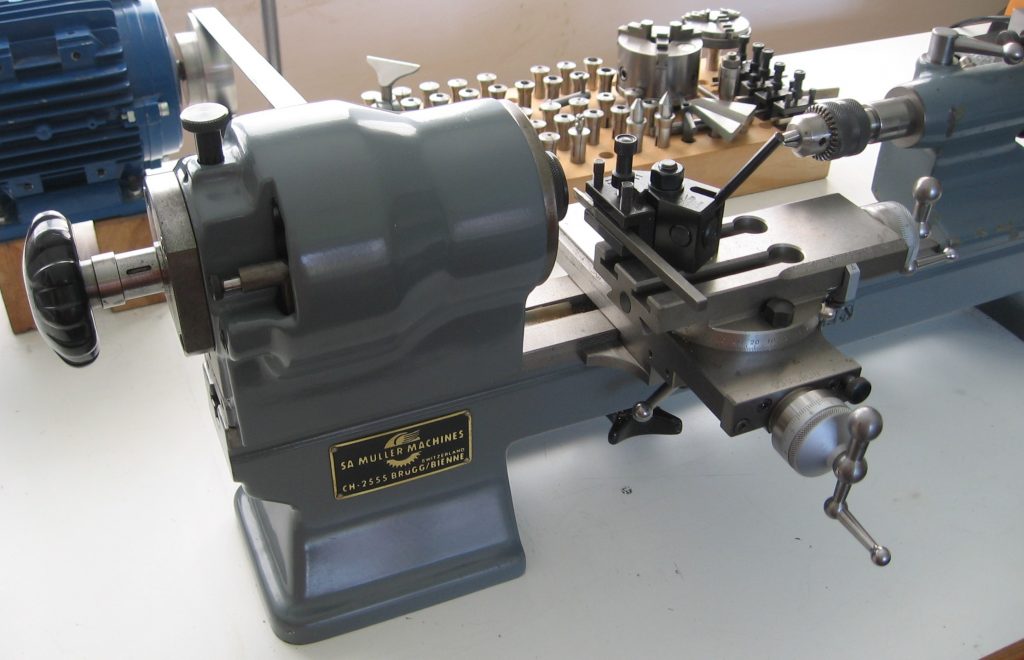

My Schaublin SV70 toolmakers lathe. This is an exceptional machine, able to turn the smallest component very accurately. The earliest of these machines were first produced in the 1950’s and it is still possible to purchase a more evolved version today, such is the usefulness of the design.

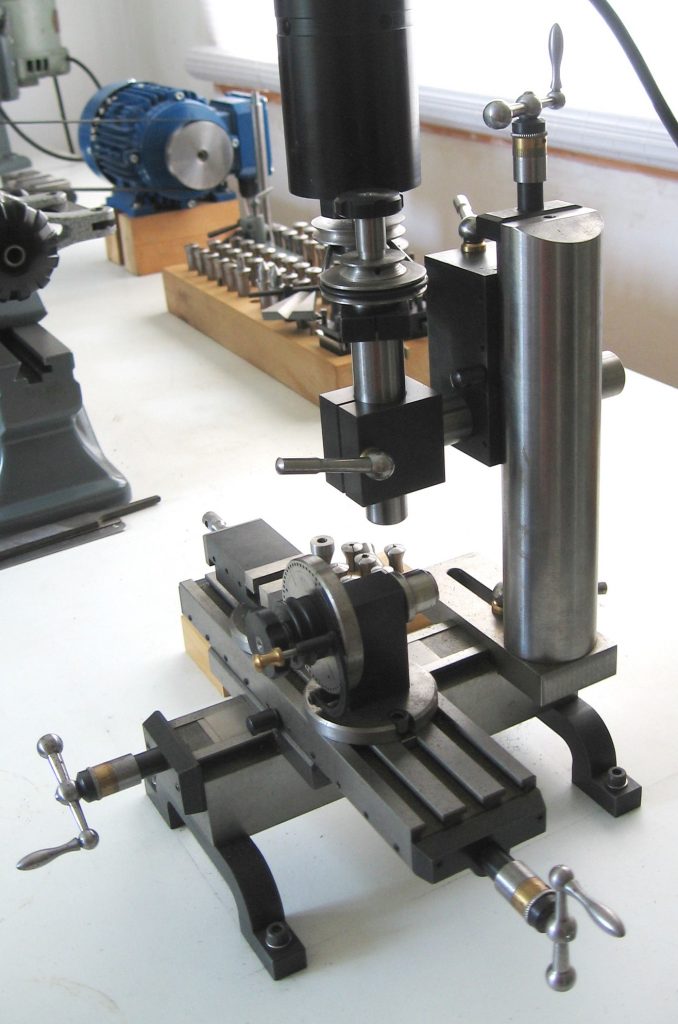

My smallest machine is this relatively modern 8mm Stevens mill. The dividing head is used very frequently to apply facets to turned workpieces. The Sixis S1101 milling machine is able to perform many varied precision tasks due to the versatile tooling acquired for it.

In addition to these machine tools there are a few others including a drill press, and a Taylor Hobson pantograph milling machine.

Beyond the relatively glamorous machine tool collection there are numerous hand tools which even thought they can be as simple as a needle file or piercing saw must still be mastered in order to make the best use of them.